In industrial applications, ultrasonic sensors are characterized by their reliability and outstanding versatility. Ultrasonic sensors can be used to solve even the most complex tasks involving object detection or level measurement with millimetre precision, because their measuring method works reliably under almost all conditions.

No other measuring method can be successfully put to use on such a wide scale and in so many different applications. The devices are extremely robust, making them suitable for even the toughest conditions. The sensor surface cleans itself through vibration, and that is not the only reason why the sensor is insensitive to dirt. The physical principle—the propagation of sound—works, with a few exceptions, in practically any environment.

The measuring method employed by ultrasonic sensors has been viewed as an excessively complex technology, and only used as a “last resort” … as a solution for particularly difficult applications. Those times have long since passed!

Ultrasonic sensors have proven their reliability and endurance in virtually all industrial sectors.

These sectors include:

- Mechanical engineering/machine tool

- Food and beverage

- Woodworking and furniture

- Building materials

- Agriculture

- Construction

- Pulp and paper

- Material handling

- Level measurement

Diffuse and Retroreflective Mode Sensors

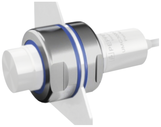

Ultrasonic sensors are most commonly used in the diffuse mode. A single ultrasonic transducer is used as both emitter and receiver and is typically contained in the same housing as the evaluation electronics.

To reliably detect difficult objects, the majority of our diffuse mode sensors can be converted to retro reflective operation via software para-meterization. Some ultrasonic sensors are supplied as retroreflective sensors from the outset.

Thru-Beam Sensors

Ultrasonic thru-beam sensors feature an extremely powerful acoustic beam. They offer a large detection range within compact housing dimensions. Unlike diffuse and retroreflective models, these sensors do not continuously switch between transmission and reception modes or wait for an echo signal to arrive. Thus, their response time is considerably faster, resulting in very high switching frequencies.

Double Sheet Sensors

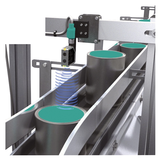

Double sheet sensors are ultrasonic thru-beam sensors that have been optimized specifically for sheet feed applications, including double sheet detection, label counting, and splice detection.

Double sheet and double material sensors distinguish between empty gaps, one, and two layers of material, including paper, metals, wooden boards, and glass panes.

When performing label detection tasks, the sensors can distinguish between the label backing and the base material.

Ultrasonic Sensor Accessories

Compatible accessories offer enormous potential for cost savings. Not only do you save a great deal of time and effort when installing the sensors, but also when servicing them. If products are used in harsh ambient conditions, appropriate Pepperl+Fuchs accessories can be used to extend the service life of the sensors.